1.Design, manufacture and installation:

● Thrust stand components: thrust measurement system, adapter, superstructure etc.

● Facility subsystems: DAQ, supply systems (fuel, oil) etc.

2.Civil construction works: site survey, building works etc.

3.Contracting:

● Turn-key – MERA is able to supply a “turn-key” test cell including civil works, thrust stand, DAQ, all necessary facility subsystems, specialized software, throttle control level and etc.

● Joint – MERA is capable to supply specified items such as thrust stand with DAQ and software. The Customer is able to procure necessary items such as test nacelle directly from OEM.

4.Project management in accordance to EPC (Engineering, Procurement, Construction, FIDIC)

5.Certification in accordance to international and local standards and rules (SAE 5305)

Engine types: PD-14, PS-90, RD-93, RD-33MK, AL-31FN

● static loading

● dynamic and life-cycle

● transporting testing (vibration table)

● thermal testing

● centrifuges

● modeling of take-off, landing modes, etc.

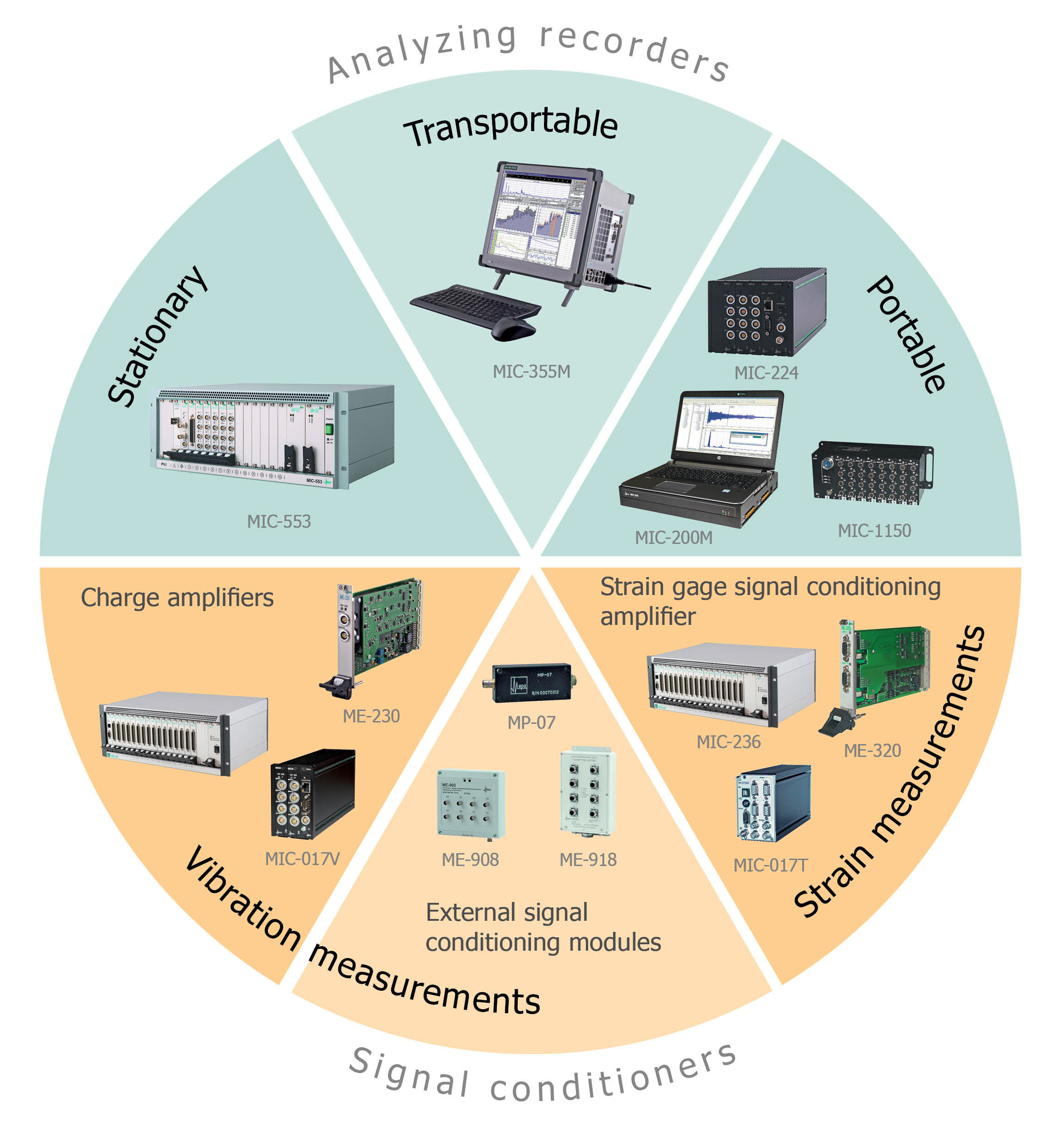

● Sampling rate: up to 216 kHz/channel

● Dynamic range: up to 120 dB

● Built-in charge amplifier

● Self-diagnostics

● Modular architecture

● Simple scalability

● Specialized software for registration, real-time analysis and post-processing

● Full set of measured parameters: temperature, pressure, digital channels, attitude, vibration, strain, frequency, video etc.

● High reliability and validity of test data

● High precision

● Hard operating conditions

● Strict requirements on power supply and heat emission

● Data transfer via HF channel to flight operation center

Components of onboard DAQ can be installed directly on object-under-test, under engine cowl and on engine pylon.

Certified against:

● GOST RV 20.39.304-98

● Aviation QR-160D

Multichannel telemetry system MIC-1500 designed to measure strain, temperature and vibration of hard-to-access rotating parts of gas turbines.

MIC-1500 is capable to operate under condition of -40…+125°C and rotation speed 18 000 RPM as well as to withstand vibration of 150 g and overloading up to 40 000 g.

● 64 strain gauge channels

● 80 temperature channels

● Up to 8 measuring modules

● Data transfer 30 Mb/s per module